Technical Ceramics

Analytical Instruments

Technical Ceramics business of Morgan Advanced Materials provides precision-engineered materials, components and sub-assemblies for spectrometric instruments.

Get a quoteAnalytical Instruments Components

Our mass spectrometry products are used in a variety of industries, including pharmaceutical, healthcare, food and environmental safety, geology, research and general industrial applications.

Similar products are also supplied for imaging instruments such as scanning electron and transmission electron microscopes (SEM and TEM) used in semiconductor inspection, healthcare, forensics, geology and research. Other imaging instruments with our products include focused ion beam (FIB) SEM.

Haematology equipment that relies upon ceramics include fluid (such as blood) collection, separation (apheresis) and analysis.

Components used in Electron Microscopes (e.g. SEM, TEM)

Components used in Mass Spectrometers

Industrial X-Ray Imaging

Charge dissipative coated ceramics

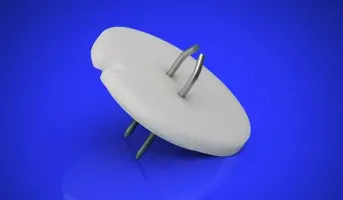

Target assembly

Need more information? Start talking to us today

Analytical Instruments Materials

Our advanced ceramic materials offer superior dimensional stability, strength, and stiffness. The resistance of our materials to chemical and physical wear, corrosion and extreme heat makes them ideally suited for use in harsh conditions. Our alumina products have excellent properties for high voltage applications and our material is formulated for bare, metallised and Ni plated products.

Analytical Instruments Capabilities

Our ceramic manufacturing process is vertically integrated from power spray drying to final tolerance grinding and our metal products (braze alloys, powders, and pastes) manufacturing is vertically integrated from alloying to forming to application, we can control and assure the consistent stringent quality standards that scientific instruments require. Whether these standards require the high-purity specifications that vacuum environments need or extremely tight-tolerance finished ground features. For example, we produce right cylinders with straightness of 10 microinch per inch and roundness less than 20 microinches.

Analytical Instruments Ceramics Questions

Why are Morgan products particularly well-suited for SEM/TEM applications?

Morgan’s AL-300® has excellent dielectric properties and is specifically designed for high voltage applications. Combined with Morgan’s braze alloy portfolio and brazing expertise, we’re able to produce high quality and reliable brazed assemblies that are used as feedthroughs for SEM/TEM instruments.

Why are Morgan products particularly well-suited for Mass Spec applications?

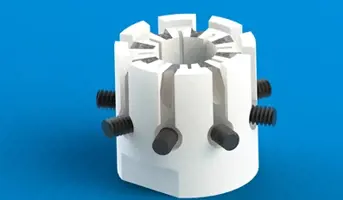

Morgan Technical Ceramics produces several high-purity alumina grades with low loss tangent that are precision machined to match the needs of ceramic quadrupole spacers and rods.

Why are Morgan products particularly well-suited for automated blood analysis equipment?

Morgan has developed ceramic materials that can be polished to less than 1 helium light band flatness, which is essential to form a hermetic seal between a stator and a rotor. These ceramics are also excellent in wear and corrosion properties, maximising the lifetime of the ceramic valves.

What unique Morgan capabilities should be considered when designing products for analytical devices?

- Material expertise – All Morgan grades of alumina are specifically designed for their applications. Each grade offers tailored solutions to the challenges of each application.

- Ceramic machining expertise – high precision machining, 5+ axis CNC machining, and years of process development deliver the tight tolerances required by analytical devices.

- Brazing expertise – Morgan is vertically integrated manufacturer of braze alloys and metallising paints with decades of brazing experience and a dedicated centre of excellence to develop new braze joint technology, working with customers to tackle complicated braze assembly challenges.