Technical Ceramics

Lasers and Optoelectronics

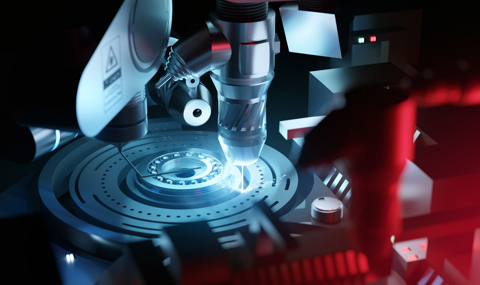

Ceramic laser components developed and manufactured by our engineers offer measurable improvements over more traditional materials in terms of lifespan, efficiency and performance. By using the expansive knowledge and expertise of our engineers, Technical Ceramics produces ceramic laser components that provide serious advantages over more traditional materials.

Get a quoteLaser Products

Our high reflectance ceramic cavities, used within laser reflectors, versus more traditional metal and polymeric parts, provide extended life-time, greater efficiency and reflectance as well as increased uniformity and thermal stability.

Feedthroughs used in gas lasers feature brazed-joint design combined with the chemical stability which allows CO2 laser manufacturers to use their systems more intensively, reduce the downtime and operating cost.

We manufacture a wide range of products for laser applications including:

Feedthroughs

Laser Reflectors

Laser Tubes

Laser Waveguides

Need more information? Start talking to us today

Laser Materials

Our ceramic wave guides and tubes are available in 94%-99.99% alumina, aluminium nitride and MACOR® and can be manufactured with high complexity in large sizes.

Our high reflectance Sintox AL laser reflectors are used for pumping within solid state lasers (100W to 500W) and intense pulse light (IPL) devices (530nm to 1000nm) specifically for use in applications such as cutting, welding, marking, eye surgery, skin rejuvenation, tattoos and hair removal.

- Sintox FF high purity alumina

- Sintox AL with solarisation resistance GSO and GSY glazes

- 94-99.99% alumina

- Aluminium nitride

- MACOR® machinable glass-ceramic

Laser Applications

The ceramic laser components manufactured by us are utilised in a variety of different applications. Within industry they are used as cutting, welding and marking lasers; in medicine they are frequently used in surgical procedures and in health and beauty industry for a variety of cosmetic treatments such as hair and tattoo removal.

- Gas lasers (CO2 for marking)

- Excimer lasers

- Industrial lasers (cutting, welding, marking)

- Surgical lasers

- Aesthetic or cosmetic lasers

- Intense pump lamp (IPL) devices

- Diode-pumped solid-state (DPSS) lasers for medical and scientific purposes

- Range finders

Laser Ceramics Questions

Why are ceramics used as laser materials?

Ceramics are specified because of ceramics’ high reflectance at critical wavelengths, e.g. 98%+ reflectance at 1064nm, coupled with exceptional and uniform thermal stability, low electrical loss, resistance to solarisation and oxidation, corrosion resistance to gases and fluids (such as fluorine compounds, CO2, cooling fluids and cleaning fluids), cleanliness, and hardness. The high reflectance is obtained by a combination of the material properties, microstructure and controlled porosity of the material.

What are the advantages of ceramic laser components over other materials?

While other materials (such as polymers, polished aluminium, and gold or silver-plated fused silica or glass) can demonstrate the required reflectance at a desired wavelength, they often lack sufficient additional attributes which detrimentally impacts long-term laser quality (e.g. thermal stability, corrosion resistance, cleanliness, durability during maintenance). Furthermore, the reflectors made out of alumina ceramic, e.g. Sintox AL, have high reflectance over a wide range of wavelengths, e.g. 98% reflectance across the wavelength range 500 – 2000nm.

How are ceramics used in laser components?

Ceramics components reflect light to concentrate the light energy to amplify an intense, coherent, collimated beam of light at a specific nominal wavelength, a “laser beam.” Because of the high-energy needs of some of these systems, ceramics are often used as electrical feedthroughs for their high electrical resistivities.