Technical Ceramics

Purity

Many applications require extremely pure ceramics to avoid potential contamination of the process or application environment. Such industries include semiconductor manufacturing, healthcare, food, pharmaceutical, and analytical equipment.

Contact usSemiconductor

Within semiconductor manufacturing, high-purity alumina and CVD silicon carbide are used as components in wafer processing equipment including plasma etch chambers, deposition and diffusion chambers, and rapid thermal processing equipment because of their high-purity and ability to withstand repeated, severe chemical and thermal cycles of the semiconductor manufacturing and equipment cleaning processes.

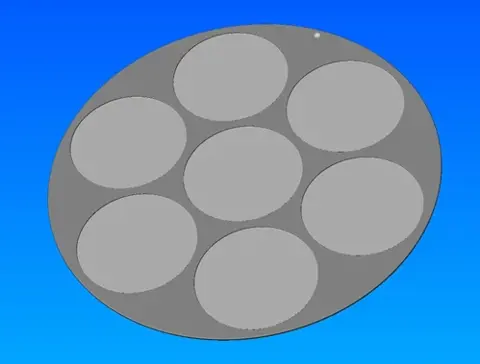

SiC Wafers

Similarly, CVD produced silicon carbide (with purity greater than 6N or 99.9999%) is being used as a high-purity source material to grow silicon carbide ingots for SiC wafers. This source material minimises impurities and defects in the resultant wafer that would impact the performance of the subsequent power device.

Transmitting Wave Tubes

Within the vacuum of space applications, such as communication satellites using transmitting wave tubes (TWTs), or the vacuum within x-ray tubes used within medical CT scanners for imaging the human body, ceramic components and ceramic-to-metal brazed assemblies need to be sufficiently pure to avoid out-gassing of contaminants into the vacuum that would degrade the efficiency of the TWT or x-ray devices.