Technical Ceramics

Electrical Resistivity

Electrical resistivity is the ability of a material to resist the transmission of an electric current. This property is also referred to as electrical volume resistivity or specific electrical resistance. The inverse measure is known as electrical conductivity.

Contact usGenerally, ceramics are excellent electrical insulators, meaning they resist transmitting electric currents very effectively. Glasses, plastics, and elastomers can also be good insulators, but other considerations, such as thermal, mechanical, and/or chemical properties, cause ceramics to be the best material choice for many applications.

Ohm-meters is the SI unit of electrical resistivity. This corresponds to a measurement of electrical resistance of a test coupon of a specified cross-section and length. Besides the coupon’s geometry, other factors that affect a material’s resistivity measure include the coupon’s surface finish, porosity, purity, and cleanliness, the test environment (e.g. temperature, humidity), the test probe geometry, and the frequency of the electrical input. The higher the measured value, the greater the resistance of the material to transmit electrical current.

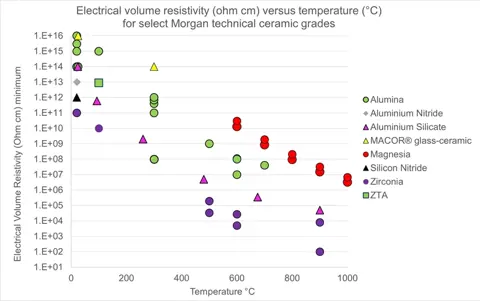

Certain ceramics offer higher resistivity values than others as shown in the chart. Because resistivity can change with temperature, it is important to specify the temperature at which a test was conducted when reporting a resistivity value.

Good Insulators

Materials are considered good electrical insulators when volume resistivity is 1 x 10^8 ohm-m and higher, or surface resistivity is 1 x 10^9 ohm/sq or higher. Some sources consider 1 x 10^5 ohm-m as the lower limit for a material to be classified as an insulator. High purity alumina and magnesia are considered good insulators.

Volume Resistivity

The upper limit of volume resistivity for conductive materials varies depending upon citation. Some list 1 x 10^2 ohm-m as the upper limits, others as 1 x 10^-1 ohm-m. Regardless, a good conductor such as copper wire is about 1 x 10-8 ohm-m. Carbons and graphites sit on the upper end of this conductivity scale. To the far left extreme of the resistivity scale are superconductors that, by definition, have zero or close to zero electric resistivity. Ceramics with perovskite crystal structure can exhibit superconductivity but only at very low temperatures and sometimes elevated pressure. Presently, cuprate, a layered perovskite structure of copper oxide, holds the current record of demonstrating superconductivity at atmospheric pressure at the highest cold temperature of 138 K (-135°C).

Semiconductors

Semiconductors are materials with volume resistivity values that fall between the lower limit of insulators and the upper limit of conductors. These are also considered as charge dissipative materials because they allow charges to flow to ground in a more controlled and slower fashion than conductive materials. This can be beneficial to protect sensitive components from damage from the build-up of electrostatic charges that suddenly arc to ground.

Ceramic Modification

Although ceramics are typically insulators, they can be modified by a variety of means (e.g. adding dopants, etc.) to improve their ability to transmit a current (reducing the resistivity value). The electrical resistance of alumina is sometimes tailored to become more electrostatic dissipative (ESD). ESD coatings are also applied to the surface of alumina components to reduce the potential for electrostatic discharge.

CVD silicon carbides are often modified to offer tailored resistivities values, known as low, medium, and high resistivity grades of silicon carbide, to assure their suitability in various applications such as plasma etch or ion implant semiconductor wafer fabrication processes.

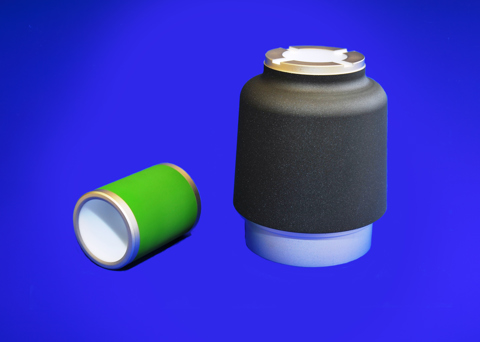

An application that requires narrowly tailored electrical resistivity is the electrostatic chuck (ESC) used in the processing steps of semiconductor chip fabrication. A sufficient electrostatic force is required to hold the semiconductor wafer at the wafer processing temperature which can range from 250°C to 700°C for deposition processes such as physical or chemical vapour deposition (PVD, CVD), or can be near room temperature for a dry etch process.

However, when the wafer is cooled, the force needs be sufficiently low such that the wafer can be removed quickly and without damage when the voltage is turned off. Because of this conflicting demand of sufficient holding force with rapid release, a narrow target range of volume resistivity, typically 10^6 to 10^8 ohm-m at the wafer processing temperature, is desired, requiring a customised ceramic, typically an alumina or aluminium nitride.