Technical Ceramics

Power Generation and Distribution

Morgan Technical Ceramics provides custom-engineered materials, precision components and assemblies that enable the generation of the world’s electricity and the transition to cleaner and more sustainable energy sources.

Get a quotePower Generation Products

Flat Glass Tempering Kiln Rollers

Investment Casting Ceramic Cores

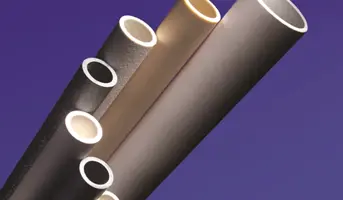

Physical Vapour Transport (PVT) / Distribution Tubes and Manifolds

Physical vapour transport (PVT) / distribution tubes and manifolds

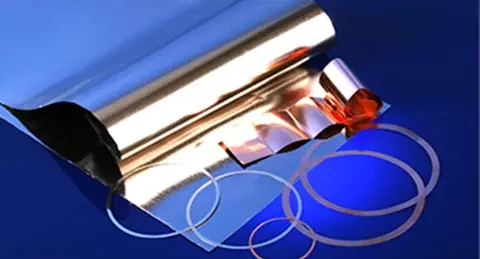

Plasma Corona Tubes

Plasma corona tubes

Thermocouple Protection Tubes

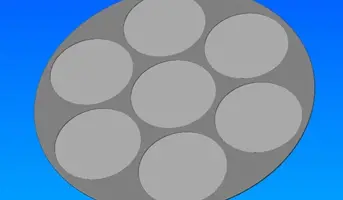

Wafer Carriers

Wafer carriers

Need more information? Start talking to us today

In 2020, natural gas-powered turbines provided about 25% of the world’s electricity, reducing the demand for coal. Morgan’s ceramic cores are essential to the manufacture of the blades within these turbines that maximise the turbine’s power efficiencies.

In 2020, about 4% of the world’s electricity was generated by photo-voltaic (PV) solar panels. Morgan’s fused silica rollers transport flat glass through tempering kilns to produce damage-resistant glass covered Gen I mono-crystalline and polycrystalline and Gen II thin film solar panels. Plasma treating of flexible films for Gen III solar cells are enabled by Morgan’s alumina plasma corona tubes.

Power electronics, which are used within electric vehicle charging stations and inverters that convert solar generated direct current into alternating current, are made using wafers made from Morgan CVD silicon carbide high-purity source material. Also, the gallium nitride or silicon carbide epitaxy layer on the surface of the wafers are deposited by MoCVD equipment that utilise Morgan CVD silicon carbide precision machined components.

The Hardware is Used Within:

- Glass tempering kilns

- Vapour distribution and deposition systems

- Film corona treatment systems

- Investment casting process

Applications:

- Gen I, II, and III photovoltaic solar panels

- Power electronics for inverters and EV charging stations

- Industrial gas turbine engines

Typical Advanced Ceramic Materials Used

Morgan is continually developing new materials and components to advance safe, efficient, and renewable methods of power generation including the latest fuel designs.

Our advanced ceramic materials offer superior dimensional stability, strength, stiffness and chemical resistance across a wide range of temperatures.

Morgan Capabilities

- Worldwide application design and engineering support

- Vertically integrated ceramic (powder, forming, finishing, coating, glazing), braze alloy (alloying, forming, finishing), and brazed assembly (metallising, brazing, coating) production

- Redundant manufacturing facilities reducing supply chain risk

- Broad braze alloy and ceramic portfolio to match application need

Power Generation Ceramics Questions

Why is high purity SiC required for SiC wafers?

High purity silicon carbide source material is typically defined as silicon carbide with a purity level of 6N (99.9999%) or greater. The purity of this source material (among other factors including its form) can influence the resulting silicon carbide crystal (or ingot) uniformity and quality from which the SiC wafers are produced. Such wafer uniformity defects can negatively affect the performance of the subsequent semiconductor power device.

Why are CVD SiC carriers used to hold wafers during the deposition of the epitaxy layer?

Solid CVD silicon carbide (SiC) wafer holders or wafer carriers are often preferred over holders made of graphite that are coated with SiC, for a variety of reasons:

- A monolithic material design can provide greater temperature uniformity resulting in a more consistent epitaxy layer deposited upon the wafer being held.

- The surface morphology of a machined, solid CVD SiC holder can be easier to control versus a coated surface morphology

- Besides being inert to the hot process gasses of the epitaxy reaction, the holder must also be able to resist the cleaning process (such as wet etching) employed to remove materials that deposit themselves onto the holder surface during the epitaxial reaction. A solid SiC carrier is considered more durable versus a SiC coated holder in both these circumstances.

What is a physical vapour transport tube?

Physical vapour transport (PVT) is a process where a source material is heated to its sublimation point, transforming the material into a gas or vapour. The PVT tube directs the flow of the resultant hot vapour to a surface upon which the vapour will be deposited, typically to form a film. Because such hot gasses can be corrosive, the tubes must be constructed of a material that is chemically inert to the hot gasses so the tube itself does not become a source of impurities in the resulting deposited film.

Related Content

- Foundry and Investment Casting Products Brochure - English

- Foundry and Investment Casting Products Brochure - Chinese (simplified)

- Ceramic Injection Moulding Brochure - English

- Ceramic Injection Moulding Brochure - Italian

- Haldenwanger Ceramic Tubes Brochure - English

- Haldenwanger Ceramic Tubes Brochure - German