Technical Ceramics

Dielectric Loss

When an electromagnetic voltage is applied to a material, some of the electrical energy is lost or dissipated due to various mechanisms (e.g. dielectric relaxation, dielectric resonance, etc.) This phenomenon is referred to as 'dielectric loss'.

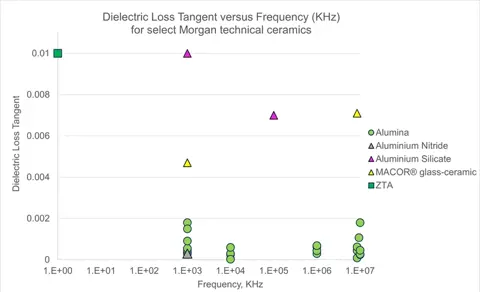

Contact usIn a ceramic the amount of loss due to these mechanisms is altered based upon the symmetry of a ceramic’s crystal structures and imperfections in the crystal lattice. Examples of such imperfections include crystal defects, impurities, porosity, grain boundaries, dopants, etc. Besides the impact of the type and the volume of imperfections upon a material’s dielectric loss, temperature and the electromagnetic frequency can also impact the amount of dielectric loss.

Whether dielectric loss is desired or not depends upon the application. For example, in a microwave oven, dielectric loss is required to cook the food. The microwave’s energy is absorbed by the water that is present in the food and the energy is then dissipated as heat, warming the food. Similarly, many industrial applications rely upon a high dielectric loss for heating and drying materials.

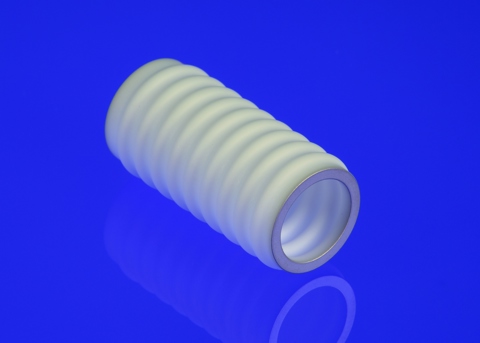

Alternatively, when specifying an electrical insulator, low dielectric loss is desired to maximise electrical efficiencies, avoid the potential of static charge build-up, and minimise heat management needs. High-voltage vacuum x-ray tubes are an example of an application that requires extremely low dielectric loss insulators.

Dielectric Loss Factor

A material’s dielectric loss factor can be expressed either the loss angle δ or the corresponding loss tangent tan(δ) also referred to as the dissipation factor (Df). A material that experiences no dielectric loss would have a loss angle of zero and loss tangent of zero.

Low Dielectric Loss

Low dielectric loss combined with low values of reflection coefficients of radio waves of certain ceramics make them particularly useful as radio-frequency transparent (RF transparent or radio-transparent) materials. Radomes protecting antennas and transmitters are an application example that benefits from such properties. Active medical implants, such as spinal cord stimulators, also rely upon ceramic (e.g. zirconia) enclosures to contain and protect electronics from the effects of internal body fluids while enabling radio signal transmission to and from external RF transmitters/receivers.